Fiber optics is the latest technology in the field of laser cutting: laser beams can reach a very high irradiance and concentrate great power in a very small area. They are now the first choice for a wide range of applications in the field of metal cutting and precision welding, micromachining of materials and laser marking.

Laser Cutting Machines for tube and sheet metal in Italy and Europe with laser power up to 20Kw, high technology to serve the best metalworking industry.

Laser Cutting Machines for tube and sheet metal in Italy and Europe with laser power up to 20Kw, high technology to serve the best metalworking industry.

Hymson systems for processing sheet metal and profiles with fibre laser technology are flexible and customisable. They provide state-of-the-art, cost-effective technological solutions for industry professionals, responding to growing demands for efficiency and performance.

FIBER LASER CUTTING MACHINES FOR THE METAL PROCESSING INDUSTRY

HOW CAN WE IMPROVE YOUR METAL WORK?

Opportunities and advantages of laser cutting

The advantages of laser cutting are mainly provided by the speed, the accuracy, the excellent finish of the cut and reduced energy consumption. Laser processing is beneficial both to the design phase and the production cycle: it is possible to work with a wide variety of thicknesses, materials and shapes. The design advantages derive from the possibility of cutting geometries on flat sheets, bent sheets or embedded sheets, by designing a working cycle that foresees the use of these surfaces later joined by traditional tools or welding.

Sheet metal, tubulars and profiles are used in machine manufacturing, precision engineering, construction, automotive, oil & gas, railways and shipbuilding: these are the sectors that benefit from laser cutting innovations and where Hymson operates with its products and technologies. In these fields the laser opens up new design possibilities and the demand significantly increases every year

Discover the wide range of Hymson proposals for the world of laser cutting of tubes and sheet metal.

The advantages of laser cutting for tubular profiles

Laser technology has significant advantages in terms of cost per piece produced and quality of the result compared to other technologies (plasma, oxyfuel). The laser performs the required machining operations with high precision and no subsequent machining with abrasive instruments is required.

The edges machined with the laser do not undergo any thermal alteration and the workpieces are ready for welding, so that a single laser operation replaces several processing steps with conventional machines.

Laser tube cutting opens new possibilities to imagine new structures while reducing the downstream manufacturing processes such as deburring, welding and assembly.

LASER CUTTING MACHINES FOR FLAT-SHEET METAL

SHEET METAL LASER – Model HF 3015 IT

ON THE OCCASION OF THE INTERNATIONAL EXHIBITION LAMIERA FIERAMILANO 2022

Hymson Italy presents the new industrial plant for flat sheet metal cutting

Model HF 3015 IT

The project developed in Italy

MADE IN ITALY

Model HF 3015 ITSHEET METAL LASER – SERIES A

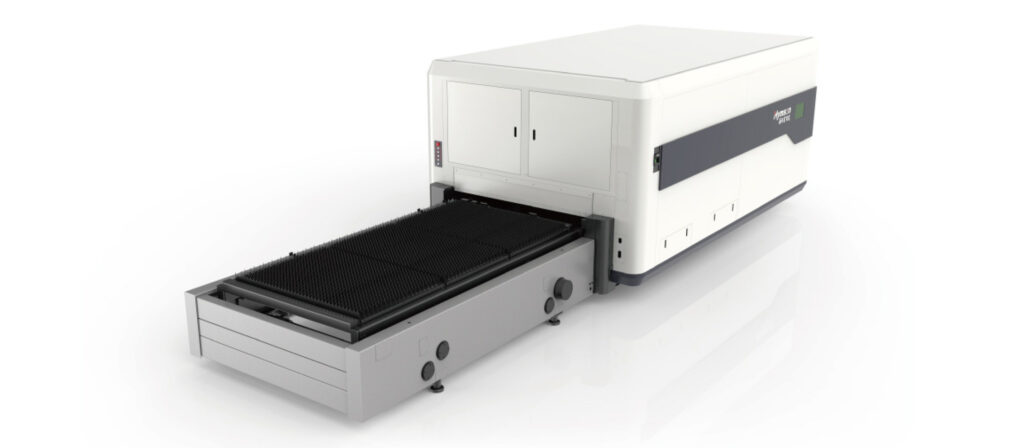

Fiber optic laser cutting machine with single table, compact and techno advanced.

The Hymson A-series fiber-optic laser cutting machine is a fast return on investment, super affordable and functional, even under not full load. Its reliability and user-friendly operation make it perfect for operators looking for efficiency and flexibility even for small productions or as a complementary machine to their production cycle.

series aSHEET METAL LASER – SERIES B

Fiber optic laser cutting machine for high quality performance.

The Hymson B-series fiber optic laser cutting machine is the most advanced choice for those who invest in the future of their business with high performance, complete and versatile technology. The fiber laser used, stable at high temperatures and vibrations, ensures long life and maintenance-free turnkey operation.

series bSHEET METAL LASER – SERIES H & G

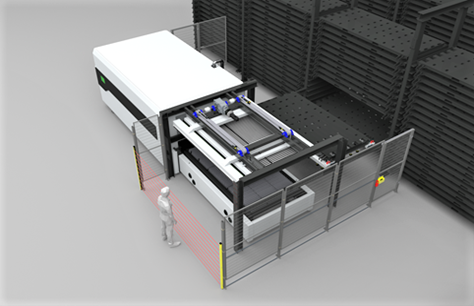

High-end laser cutting machine suitable for the installation of automated loading and unloading systems.

The HF H series is a fully automatic cutting solution with high power laser source up to 12 kW. With exceptional performance in terms of reliability, precision and rigidity, the system is equipped with an innovative “up & down” exchange table and can be integrated with automatic loading/unloading and multi-storage tower systems.

SERIES H & GAUTOMATIC LOADING SYSTEMS

Fully automatic loading and unloading system for Flat Sheet laser cutting machines.

The system fully automatically controls the material to be processed to the laser exchange table during both loading and unloading stages. the operator only duty is the handling of the batch of sheet metal in the loading area and picking up the cut pieces.

AUTOMATIC LOADING

LASER CUTTING MACHINES FOR TUBE

TUBE LASER – SERIES HP-D

HIGH-END SYSTEM WITH THE MOST ADVANCED TECHNOLOGY FOR TUBE AND PROFILE CUTTING.

The winning choice for the most demanding industry asking for top cutting performance to achieve burr-free and flake-free surfaces, maximum reliability and excellent value for money.

SERIES HP-D

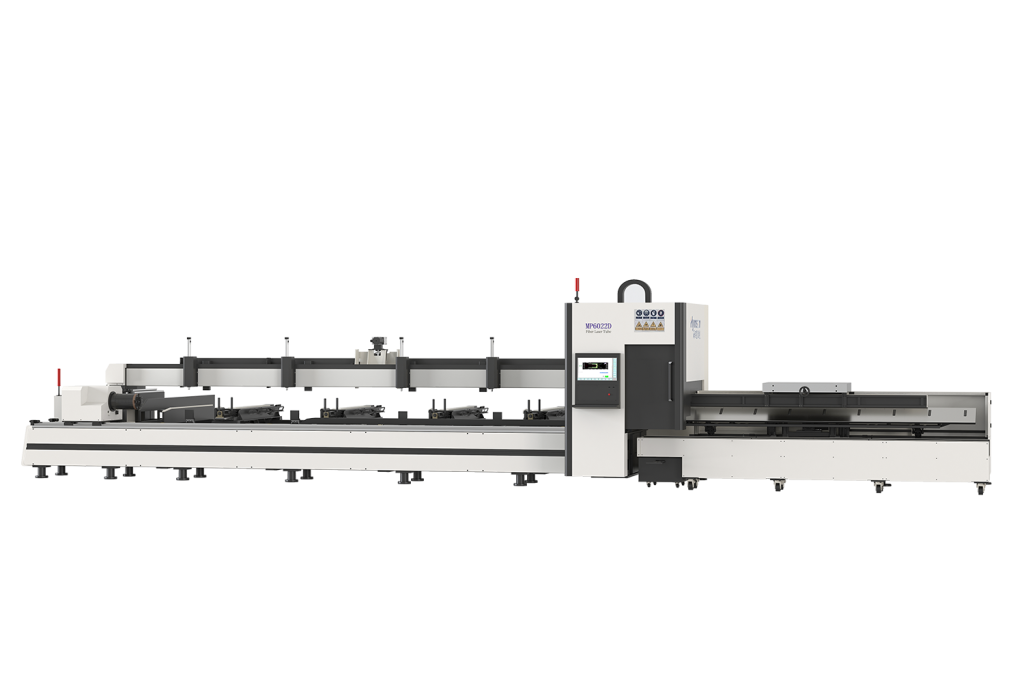

TUBE CUTTING SERIES MP

Robust, reliable and designed for high-intensity production, the machine replaces conventional production technologies and offers excellent access to the tube processing industry.

The MP series is the ideal and economical laser cutting machine for a variety of tube types and thicknesses. Equipped with automatic loading and unloading system, the MP series can run smoothly 24/7 with a high production rate, low running costs and high overall benefits.

SERIES MPSERIES TP / 3-CHUCK LASER TUBE

SERIES TP: VERTICAL FRAME LASER TUBE WITH 3 CHUCKS

The tube laser cutting system suits heavy duty tube working with state-of-the-art technology, full length cutting and zero scraps. The three-jaw chuck is a brand-new mechanism used to process long and heavy tubes. The system, at the top of the range in laser tube cutting, is highly automated, with five-axis, ultra-fast rotation and high-precision positioning.

Available models: TP 6026 | TP6035 | TP 9035

SERIES TP 3-CHUCKSERIES FP / 4-CHUCK LASER TUBE

SERIES FP: HEAVY DUTY GANTRY MACHINE WITH 4 CHUCKS

High-end performance fiber optic laser cutting machine for TUBES and PROFILES. Hymson FP SERIES tube laser cutting system has been completely upgraded and refurbished, highly improving the processing efficiency. It is fitted with a four-jaw customised chuck, a brand new mechanism suitable to process long tubes and heavy pipes.

Available models: FP 12035 | FP 12056

SERIES FP 4-CHUCKSERIES X2 COMPACT TUBE CUTTING

AN ALL-IN-ONE, COST-EFFECTIVE SOLUTION FOR ROUTINE SMALL SIZE TUBE CUTTING

Hymson X2 SERIES high-speed fibre laser cutting machine, compact and integrated with automatic loading and unloading system, is designed for small tubes cutting. The automatic loading system lifts the conventional 6 mt batch of raw material into the storage rack. The automatic loading | automatic feeding | automatic cutting and automatic release are provided for the entire process.

SERIES X2COMBINED LASER CUTTING MACHINE – SERIES HF 3015 BP

A single plant for both FLAT SHEET-METAL and PIPE cutting.

A single plant for both sheet metal and pipe cutting. With this new combined Hymson machine you can manage sheet metal and tube processing and approach new industrial applications with considerable savings on investment and space.

SERIES HF 3015 BP

INDUSTRIAL APPLICATION

Sectors

- Automotive industry

- Oil & Gas

- Aviation industry

- Energy

- Sheel metal

- Ship building

- Electronic cabinets

- Engineering

TECHNICAL SERVICE AND ASSISTANCE

The value of a good choice is measured over the future

Service means responding quickly to the questions of those who use your machines. With an advice to reduce downtime, an operative explanation for the realization of a specific part, an intervention to solve a technical fault, a supply of spare parts, an additional training session, an operational indication to use the system to its full potential.

The laser cutting system is serviced by qualified Hymson technicians both during the warranty period and beyond with long-term service contracts. Contact the Hymson Italy office, you will also receive free remote consultation through Wechat/Whatsapp support.

Request the technical assistance on site: a dedicated external service will be able to resolve any problem on the system.

Reliability is the key to the operation of a successful system and innovative maintenance management of capital goods starts with performance monitoring to plan routine maintenance, manage unforeseen faults, plan the supply chain of spare parts and materials, anticipate and solve any breakdowns.

Participate in Hymson Italy technical-commercial training courses to increase technical and commercial pre/post-sales expertise, to create product confidence, achieve operational problem-solving skills and help optimize machine performance, thus increasing efficiency and productivity.

Italiano

Italiano Français

Français Español

Español