Hymson plants for flat sheet and tube metal working

Green evolution

Towards sustainable and circular design models in industrial plant engineering

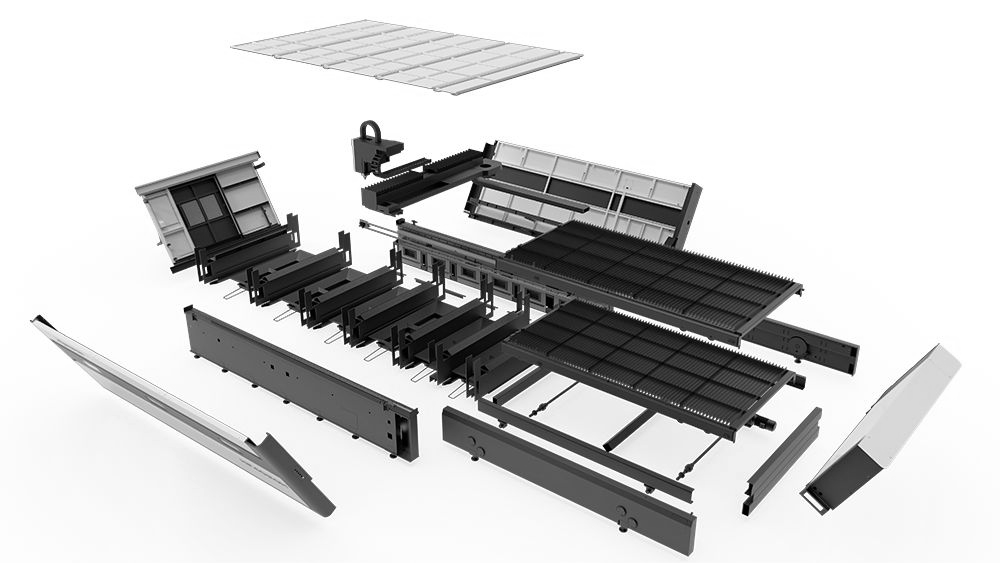

HYMSON laser cutting systems are designed in modules. Integrating different components with independent functions into a single system helps to improve the speed of product development and respond quickly to the market’s demand for customisation.

One of the guiding principles is easy accessibility to parts or components of the plant that are subject to scheduled maintenance operations (diagnostics, maintenance, repair).

One of the priorities in the development of circular design models is the so-called modularity of plant systems. The concept of modularity, which defines a component within a larger system, is the basis, in fact, of a high level of economic savings linked to the management of the plant. It often happens, even in the case of recently designed and built plants, that accessibility to the various parts of the plant is made very difficult due to a design that is entirely oriented towards solving the production problem, rather than facilitating the need for control – diagnostics, maintenance, repairs….

In order to trigger this design vision, it is therefore necessary to create a guideline for decommissioning in a circular perspective, right from the project development phase, which takes into account the end of life of the materials and components of the plant and the ease of maintenance.

WHY BRING THE CONCEPT OF CIRCULAR DESIGN TO INDUSTRY?

- This type of design is taking on a strategic importance in the European circular economy scenario, changing the very concept of traditional design in favour of a more comprehensive vision, which has as its priority not only the production of goods, but also the end-of-life management of the industrial plant itself, allowing the recovery of a large quantity of materials, transforming them into materials with a high economic value and at the same time encouraging a reduction in waste.

- Introducing the concept of “design to disassemble” into the design and construction of a new industrial plant changes the design paradigm and develops a completely new approach, with both environmental and economic benefits. In fact, designing to disassemble means making it possible to recover and recondition large and small parts of a plant at a sustainable cost that would otherwise be lost during maintenance or decommissioning.

Designing to disassemble means making it possible to recycle and recondition of large and small parts of the plant at sustainable costs, which would otherwise have been lost during maintenance or decommissioning.

Today, in fact, beyond the financial value of the asset produced, industrial plants bear very high costs due to the ordinary and end-of-life management of the plant. This happens because the way industrial plants are designed does not solve the problem of maintenance and end of life, but only that of the production of goods.

System components

Refrigeratore

Sostegno tubi

Sostegno

Motori

Testa taglio

Trave alluminio

Struttura di protezione

Aspiratore polveri

Tavola di avanzamento

Aspirazione smart a zone

Sorgente laser

Struttura basamento

English

English Italiano

Italiano Español

Español

HYMSON ITALY

HYMSON ITALY