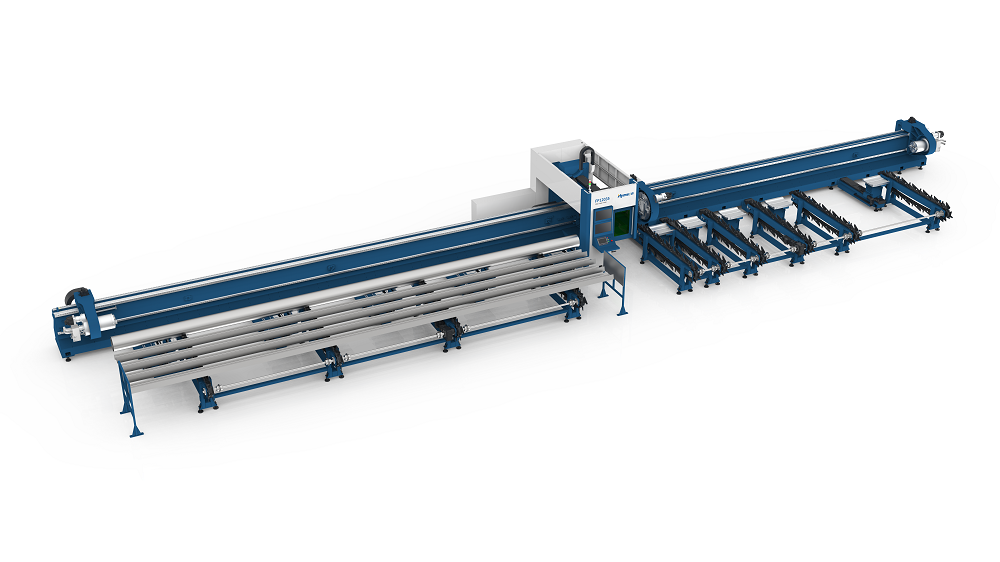

SERIES FP: Heavy duty gantry machine with 4 chucks

Hymson FP SERIES tube laser cutting system has been completely upgraded and refurbished, highly improving the processing efficiency. It is fitted with a four-jaw customised chuck, a brand new mechanism suitable to process long tubes and heavy pipes.

High-end performance fiber optic laser cutting machine for TUBES and PROFILES

The FP SERIES is the winning choice for the most demanding industry that requires high cutting performance to obtain surfaces without burrs or flakes, maximum reliability and excellent return on investment. The system, at the top of the range in laser tube cutting, is highly automated, with five-axis linkage, ultra-fast rotation and high-precision positioning. As to the control, the world’s top brand CNC Esa Automotion and the first-class high-power laser are used to make it an advanced numerical control laser tube cutting machine integrating high stability, high precision and high performance. The automation of all operations results in significant time savings and a controlled step-by-step process that is not just depending on the operator’s technical skills. The machine can process a wide variety of shapes, opening up new areas of industrial application.

Model FP 12035 | Model FP 12056

- The laser tube cutting machine is equipped with an efficient gantry-type structure.

- Automatic loading and unloading system ideal for bulk batches and for picking up single pipes from a bundle of material.

- Continuous processing 24/7 and highest productivity.

- Maximum workable bar weight: Kg/m 150 (1800kg/each tube)

- Automatically loadable bar length: from 12000 mm

- Maximum workpiece length: 12000 mm fully machined; longer tube cutting on request

- The dust and smoke removal system ensures high environmental performance.

- The ESA Automotion CNC is a control automation technology with outstanding performance, versatile and self-explanatory in the configuration.

- The software developed by Hymson R&D department as an innovative dialogue interface man-machine.

- The motor gears, toothed racks and gearboxes are of well-known and reliable brands.

- Protection class IP 54

Nesting software

The Tube CAD/CAM software controls all tube and profile cutting systems (3-, 4- or 5-axis machines with one or more spindles and robot cells for tube and profile cutting).

All steps of the programming process are managed: CAD import or drawing of tubes and profiles, management of production orders, automatic nesting of tubes or profiles to be cut, creation and automatic sequence of paths, generation of NC files. The software works automatically but leaves the user the possibility of managing special situations to ensure optimal programming.

The software manages:

- CAD import of unit parts or assemblies, with quantity recovery.

- Automatic recognition of tube sections and profiles.

- Automatic development and straightening of tubes and profiles.

- Automatic generation of paths and cutting program for tubes and profiles.

Automation management (automatic programming of loading/unloading systems, coupling and clamping spindles).

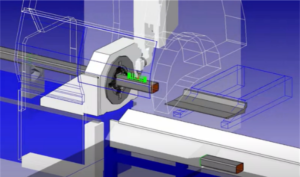

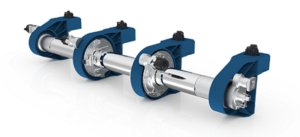

Four-jaw chuck

Precise detection of jaw clamping status and tube size to solve the challenges of machining long and heavy workpieces.

Intelligent tube support device, providing multi-point support technology to avoid slamming when machining large tubes.

Clamping detection to avoid accidental disengagement collisions.

Loading and unloading system

The loading device features multi-mode chain. Semi-automatic feeding can be realized.

Loading system

The system allows to automatically load a single tube from a step loader and is useful in the processing of small batches. The system automatically corrects the position of the tube on the worktable, thus guaranteeing maximum position accuracy.

Wide range of workable tubes in terms of material, weight, and shape.

The length detection function shows the length of each tube to be machined.

The speed of feeding could be programmed or manual adjustment, this could be adjusted for big and small size of tubes.

Unloading system

The unloading table is a flexible lifting platform for workpieces longer than 1200mm and up to 9000mm.

Its function is to separate finished parts from scraps.

Technical specification FP SERIES

Parameter |

Model FP 12035 |

Model FP 12056 |

|

Fiber optic laser power |

1000-6000 W |

||

Tube type |

Shape: Round, Square and Rectangle.Material: SUS, MS.Customization for Angle, Channel profiles, H beam |

||

Tube size |

Round Ø 20-350mm |

Round Ø 30-560mm |

|

Max weight single tube |

1000kg |

1800kg |

|

X AXIS |

|||

Stroke length |

0~400mm |

0~600mm |

|

Positioning accuracy |

0.03mm |

0.03mm |

|

Positioning speed |

Max 60m/min |

Max50m/min |

|

Repetition positioning accuracy |

±0,03mm |

±0,03mm |

|

Y AXIS |

|||

Stroke length |

0~12200mm |

0~12200mm |

|

Positioning accuracy |

0.05mm |

0.05mm |

|

Positioning speed |

Max 50m/min |

Max 30m/min |

|

Repetition positioning accuracy |

±0,03mm |

±0,03mm |

|

Z AXIS |

|||

Stroke length |

350mm |

500mm |

|

Positioning speed |

Max 50m/min |

Max50m/min |

|

Positioning accuracy |

0.03mm |

0.03mm |

|

Repetition positioning accuracy |

±0,03mm |

±0,03mm |

|

B1, B2 and B3 AXES |

|||

Rotation speed |

50rpm |

25rpm |

|

TUBE LOADING & UNLOADING |

|||

Step type automatic loading system |

|||

Max tube length with automatic loading |

12000mm |

12000mm |

|

Max. auto-loading weight |

Up to 3tons |

Up to 5tons |

|

Automatic loading round tube |

Ø 20~320mm |

Ø 30~520mm |

|

Manual loading round tube |

Ø 20~350mm |

Ø 30~560mm |

|

Automatic loading square tube |

Ø 20 ~ 220mm |

Ø 30 ~ 360mm |

|

Manual loading square tube |

Ø 20~ 250mm |

Ø 30~ 400mm |

|

Max. tube length unloading |

9000mm/12000mm |

9000mm/12000mm |

|

Max weight single tube |

1000kg |

1800kg |

|

Scrap length |

≥300mm;≥0mm |

≥350mm;≥0mm |

|

Final length |

0mm-1200mm;≥1200mm |

0mm-1400mm: ≥1400mm |

|

Option |

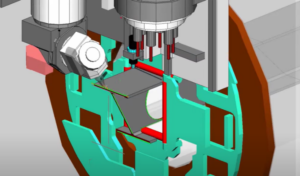

Tilting head |

Tilting head |

|

Cutting capacity

|

|

MODEL FP 12035 |

MODEL FP 12056 |

TUBE |

Ø 20 to ø 350 |

Ø30 to ø 560 |

SQUARE |

20×20 to 250×250 |

30×30 to 400×400 |

RECTANGULAR |

20×20 to250×200 |

30×30 to400×200 |

OVAL AND ELLIPTICAL |

20×20 to 250×200 |

30×30 to 400×200 |

ANGLE and L-SHAPE |

20×20 to 200×200 |

20×20 to 200×200 |

FLAT |

20×20 to 280×20 |

20×5 to 300×15 |

UPN |

20×20 to 280×130 |

20×20 to 400×160 |

WINDOWS AND SPECIAL SECTIONS |

On request |

|

English

English Italiano

Italiano Español

Español